Rubber parts are manufactured for many industries but one of the largest is the oil and gas industry. Just some of the parts required by these industries include things like gaskets, O rings, valves and diaphragms, for example. These parts can be made from a wide range of different polymers, all with individual properties and manufactured using a number of different moulding processes. Find out more about UK Rubber Moulding from a site such as https://www.meadex.co.uk/rubber-moulding/

The different sectors of this industry that require rubber components include oil and gas exploration, pipelines, production, storage and petrochemical plant operations. Parts can be required for a vast array of processes such as drilling, wellheads, processing and distribution. These parts could include:

- Gaskets needed for pumps, turbines, compressors and valves

- O-rings to be used for wells, drilling and distribution

- Valves for use anywhere there is a flow of gas or liquid through pipes

- Regulator seats for use regulating high pressure applications and shut off processes

- Diaphragms for pump flow control, both static and dynamic.

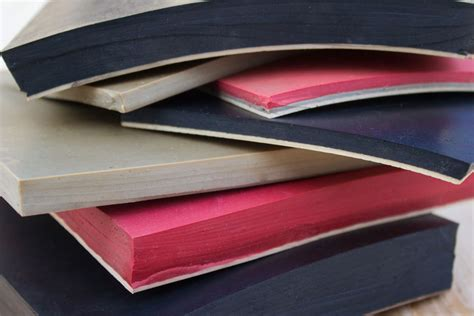

Rubber comes in a variety of properties that can be adjusted to suit particular applications. Some materials can be produced with a compound that makes it more fluid resistant, whereas another can be made to offer higher temperature strength. For the oil and gas industry, these materials must be tough as they are used in environments that can be both extreme and harsh. Some of the materials used include:

NBR or Nitrile – a general purpose rubber that can come with low temperature resistance

HNBR – Ideal for explosive or decompression applications and has high resistance to heat, chemicals and abrasion

FKM or fluoropolymer rubbers – good for applications where resistance to chemicals, ozone, weather, heat, oxygen and burning is required

FEPM – highly resistant to ammonia, organic substances, steam and heat applications

FFKM – resistant to almost all chemicals and can withstand very high temperatures

EPDM – highly durable, good for steam and outdoor applications but not for contact with petroleum.

The ideal characteristics that rubber materials need for use in this industry include the following:

Compression – the ability to bounce back once a force of compression is removed

Abrasion – a material’s ability to withstand removal of surface from constant wear

Chemical resistance – to be able to withstand short or prolonged exposure to chemicals

Tear strength – the ability to resist being torn or cut in the direction of stress applied

Tensile strength – resistance to being stretched

Extrusion resistance – be able to withstand both high pressure and high temperature environments

Low friction – important for contact with rough materials

Corrosion resistance – the ability to withstand exposure to corrosive gases

Resilience – the ability to stand up to a range of different stressors

Temperature resistance – the ability to stay strong in extremes of temperatures both hot and cold

Elongation – the ability to be stretched without breakage occurring

As you can see, there are many different qualities that rubber may need to have in order to provide a tough component for harsh environments and prolonged use.

Average Rating