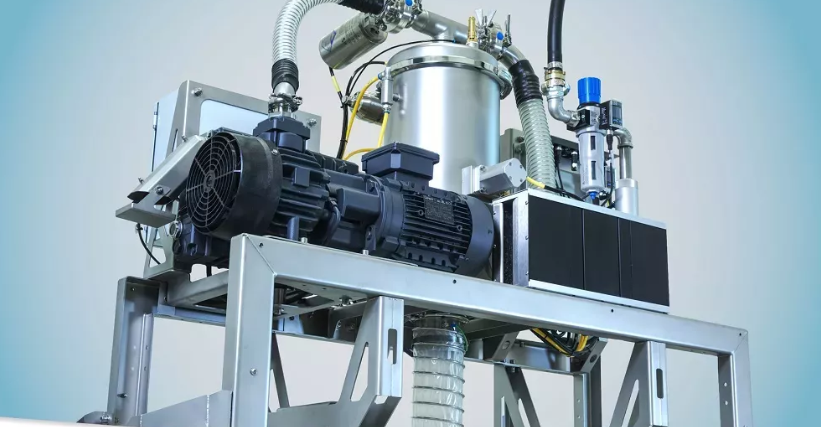

Pneumatic conveying is a sophisticated method of transporting bulk materials using air pressure or vacuum systems. Let’s take a look at the types of pneumatic conveying systems and their applications in various industries.

Understanding pneumatic conveying

Pneumatic conveying involves the movement of dry bulk materials, such as powders, granules, and pellets, through pipelines using air as the conveying medium. The process relies on the principle of fluidisation, in which materials are suspended and transported within an airstream, allowing for efficient and gentle handling without the need for mechanical conveyors.

Types of pneumatic conveying systems

According to GlobalSpec, there are three primary types of pneumatic conveying systems: dilute phase, dense phase, and semi-dense phase. Dilute phase conveying uses high-velocity air streams for lightweight materials over long distances. Dense phase conveying employs slower, denser flows suitable for fragile or abrasive materials, minimising degradation. Semi-dense phase falls between these two, combining aspects of both for versatile handling.

Applications in industries

Pneumatic conveying systems find widespread applications across various industries, including food processing, pharmaceuticals, chemicals, plastics, and mining. In the food industry, pneumatic conveying is used for transferring ingredients, such as flour, sugar, and spices, between processing stages without contamination or loss of quality. Similarly, in the pharmaceutical sector, pneumatic conveying ensures the hygienic and precise transfer of powders and granules for tablet compression and packaging.

For those who are interested in learning more about the advantages of pneumatic conveying and their applications, companies such as www.aptech.uk.com/pneumatic-conveying-systems/ can assist.

In conclusion, pneumatic conveying presents a versatile and efficient solution for bulk material handling across industries. Its capability to transport materials with minimal degradation, contamination and energy usage makes it highly favoured. With ongoing technological advancements, pneumatic conveying systems are poised to evolve to meet the increasing demands of modern manufacturing.

Average Rating